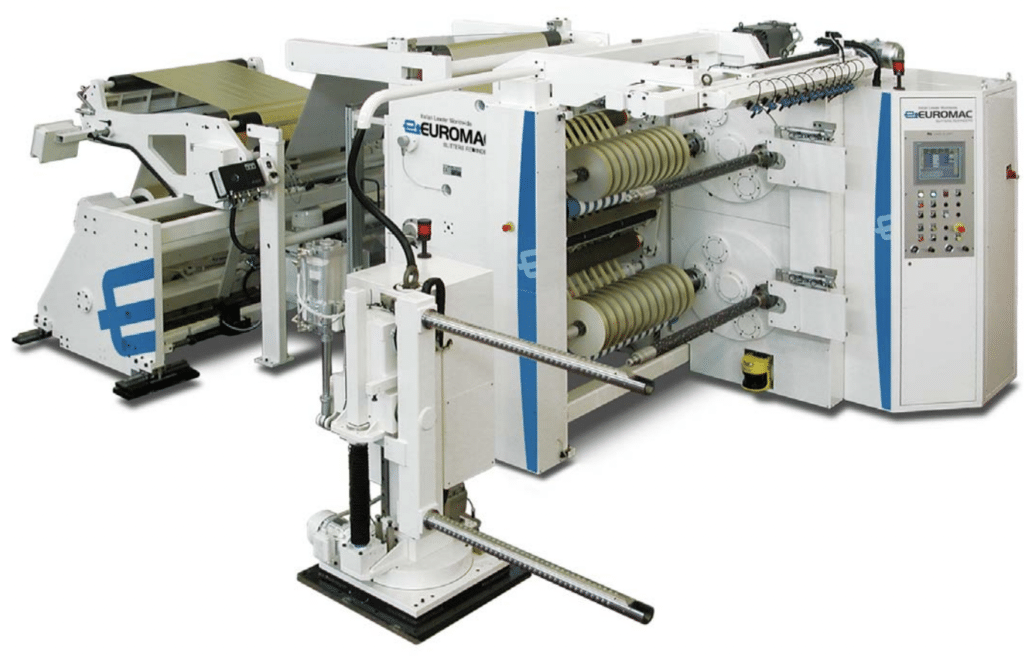

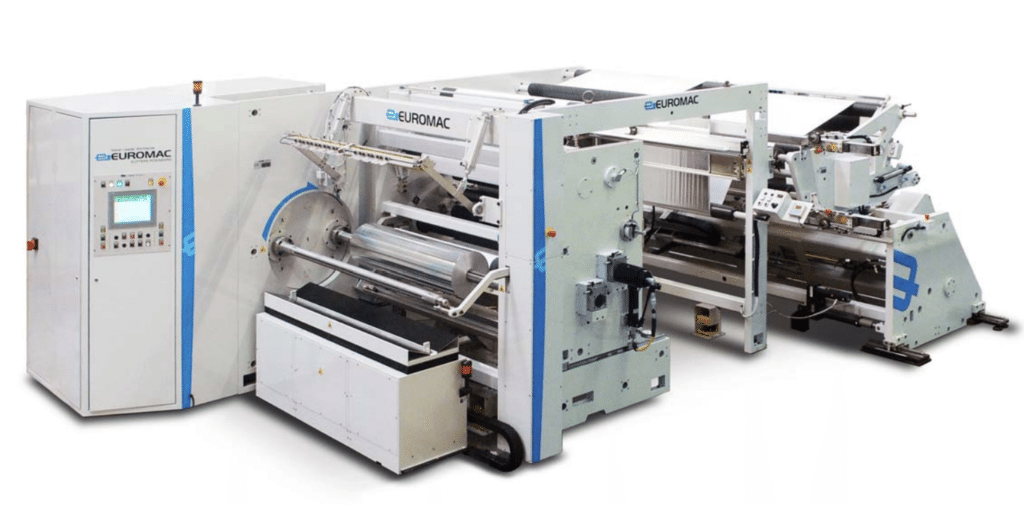

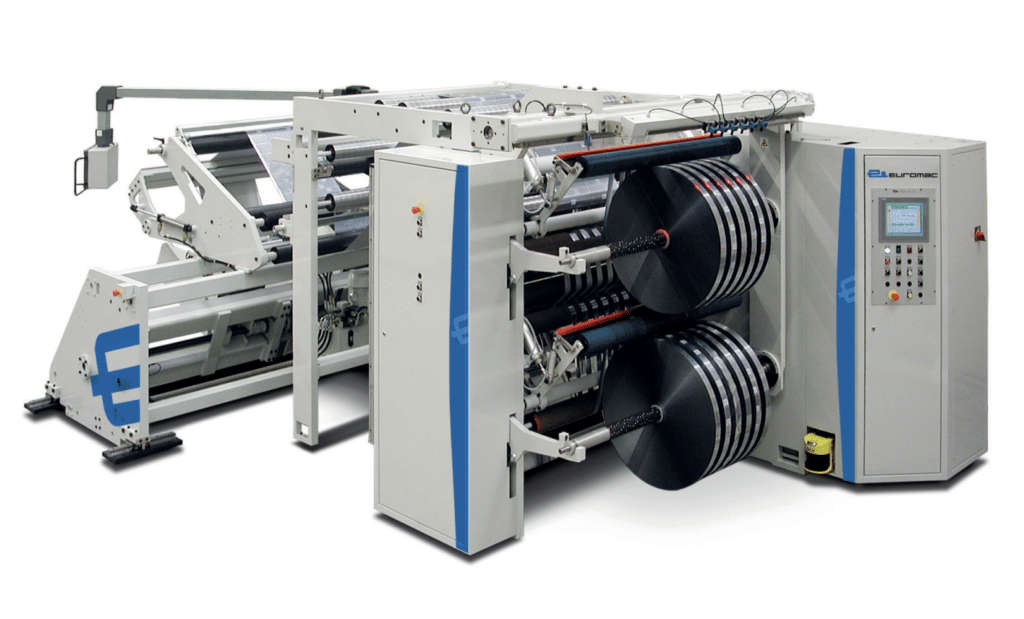

Double Turret Slitters – TB-3T2

Get versatile roll machine slitters for flexible packaging. TB-3 series delivers precise rewinding and cutting: duplex/single shaft functions & automation.

UNWIND – Choice of Shaftless or Shafted Unwind Stand. Dancing roller for precision tension management. Option of Pneumatic Brake or Electric Motor. Automated edge guiding system.

SLITTING – Oscillating razorblades and/or shear-cut circular blades for slitting. Blade holders mounted on shafts or linear bearings • Blade positioning adjustable from manual to semi-automatic, to fully automatic.

WEB PATH – Aluminum idler rollers form an overhead bridge • Driven main pull roll equipped with a pressure roller or “S” wrap system.

REWIND – Duplex Turreted Rewind, supported by lay-on rolls • Swift automatic cycle for reduced downtimes of about 30 seconds • Automated transversal splice sequence • Choice of Differential Friction shafts or Air Expanding shafts • Independent lay-on units with adjustable pneumatic pressure • Core positioning manually or aided by laser pointers or an automatic loader • Roll removal facilitated by a twin bar device or powered trolley.

AUTOMATION – Integrated PLC overseeing all machine functionalities and controls • Interactive touch screen for operator commands • Modem connectivity for external monitoring.

Read more about product and technical specifications under “Datasheet”