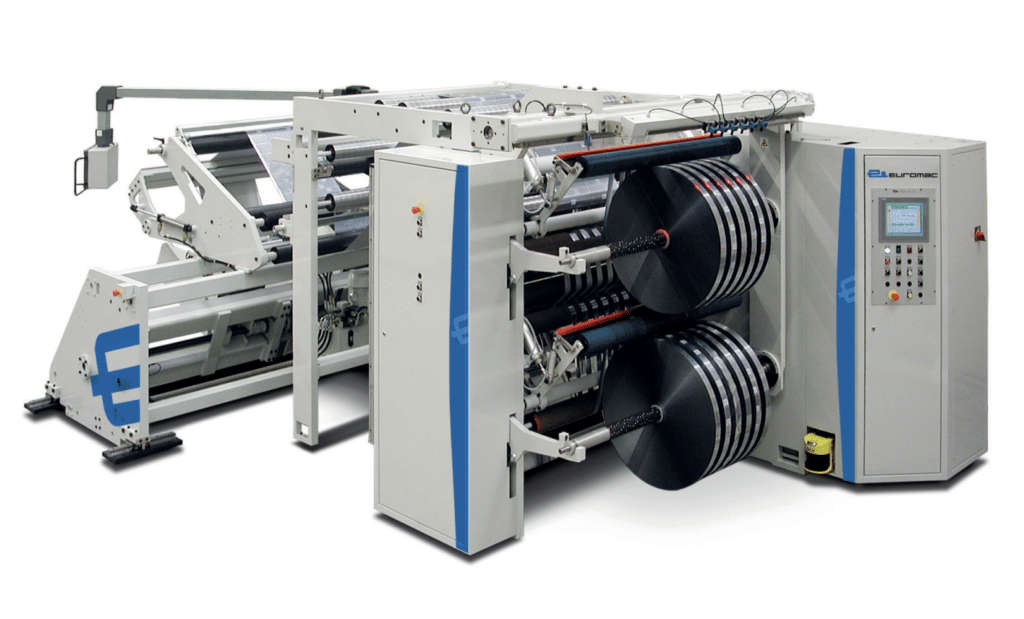

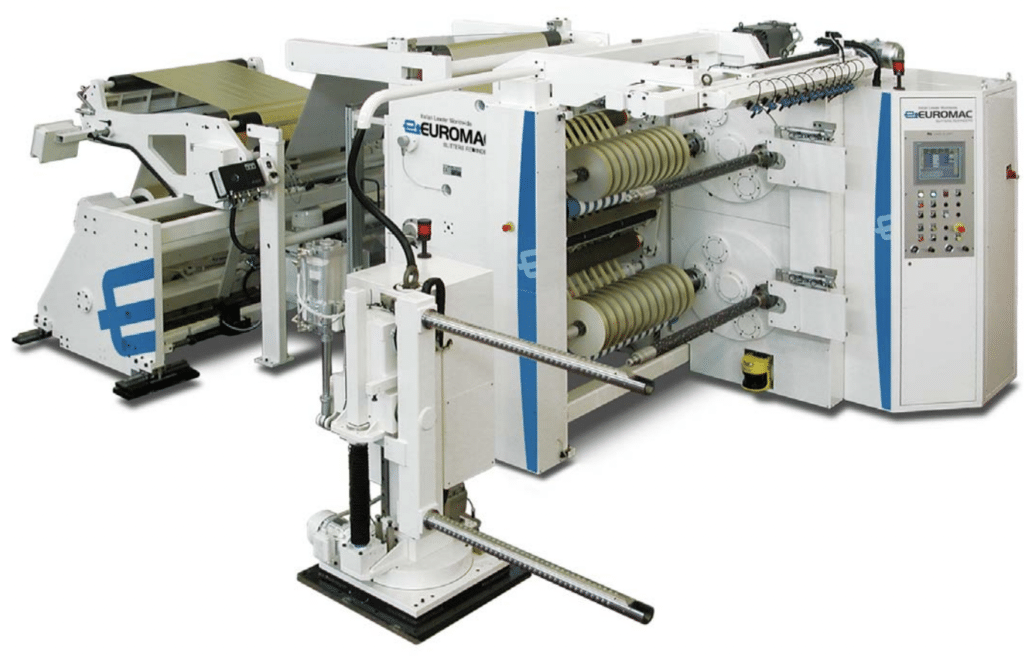

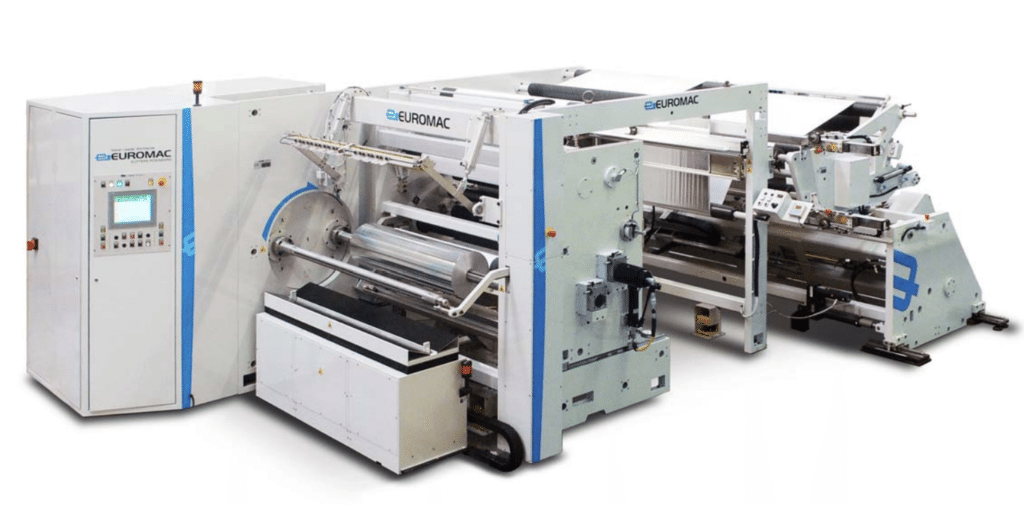

Advanced Slitting Machine Features for Precision and Efficiency

Get versatile roll slitting machine for flexible packaging. TB-3 series delivers precise rewinding and cutting: duplex/single shaft functions & automation.

UNWINDING – Features a distinct unwinder, available in both shaft and shaftless configurations. Incorporates a dancer roller for precise tension management. Options for tension adjustment include pneumatic brakes or an electric drive. Equipped with an automated web alignment system.

SLICING – Utilizes either an oscillating blade or a rotary shear cutting mechanism. Mounts the knife on either a shaft or along linear tracks. Designed with a specialized belt path for either wrapped or direct edge cutting. Offers manual, semi-manual, or fully automated knife adjustment options.

BELT – Utilizes an overhead bridge for belt routing • Fitted with aluminum support rollers • Includes both a driving roller and a pressure roller, alternatively known as an “S” drive configuration.

REWINDING – Equipped with a dual-shaft rewinder featuring contact rollers • Options for shaft engagement include ball clutch mechanisms or pneumatic expansion • Features independently controlled contact rollers with pneumatic adjustment • Multiple system options for tension regulation • Offers manual core placement, precision laser-guided alignment, or an automated loading system • Discharges reels using either a flag drop system or a powered cart.

CONTROL SYSTEM – Incorporates a Programmable Logic Controller (PLC) for comprehensive machine operation and functionality oversight • Features a touch-sensitive operator interface • Equipped with a modem for off-site monitoring capabilities.

Read more about product and technical specifications under “Datasheet”

See TB-3 Slitting Machine in Action