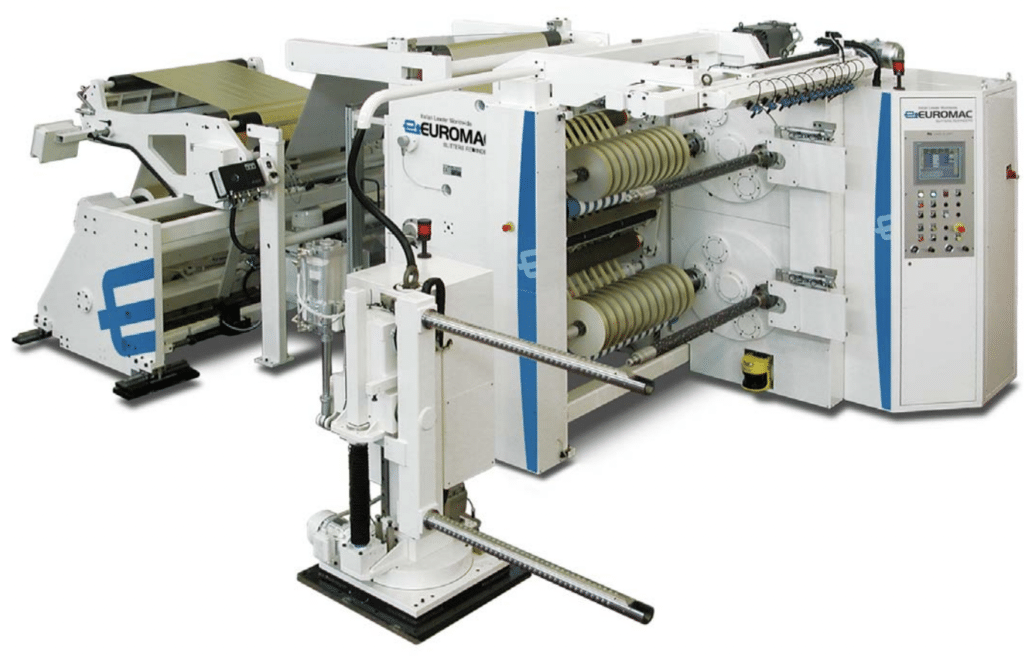

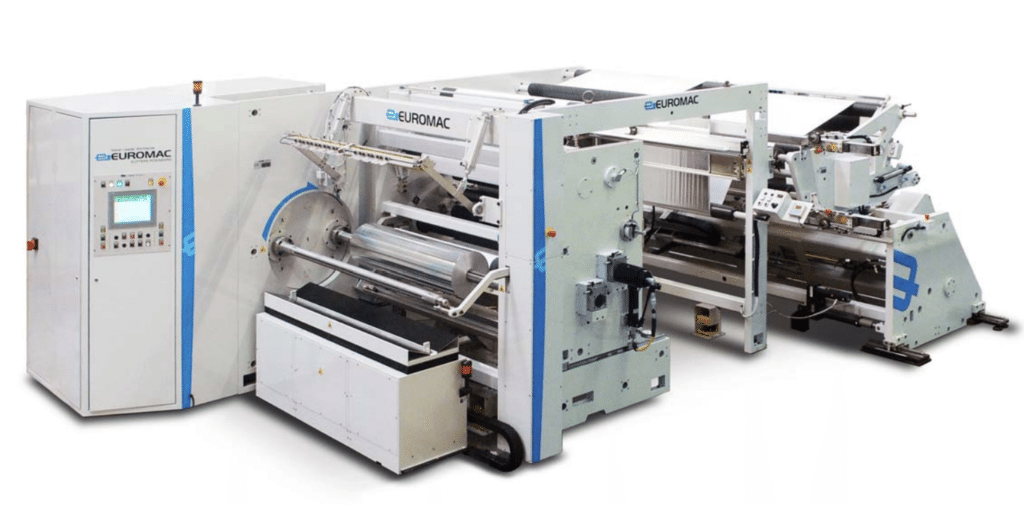

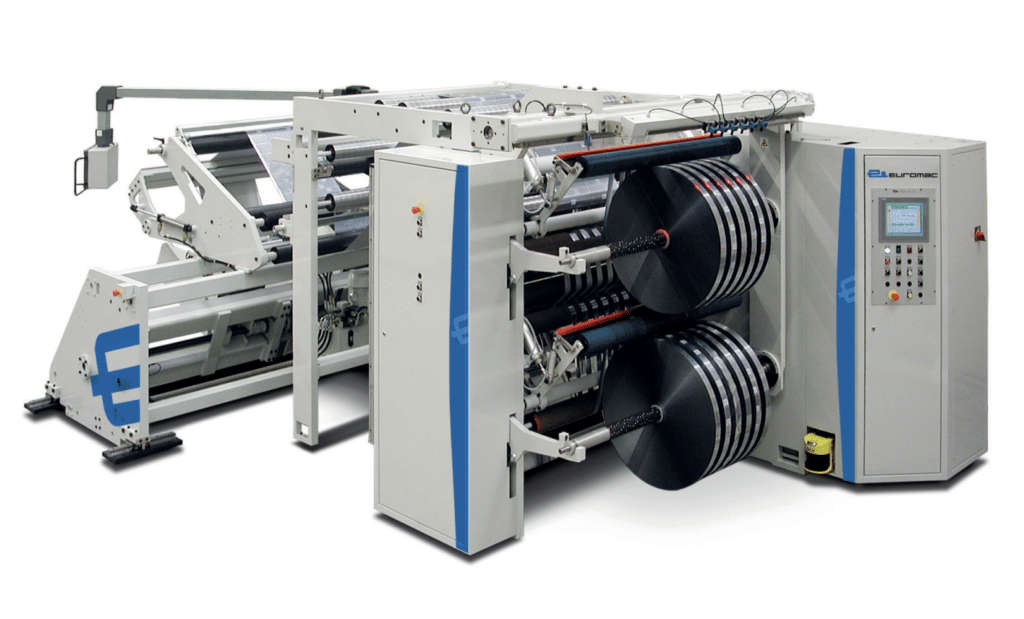

Semi-Compact Duplex Roll Slitter Machines from Euromac

Get versatile roll slitter machines for flexible packaging. TB-3 series offers precise rewinding and cutting: duplex/single shaft functions & automation.

UNWINDING – Integrates an unwinder with options for both shaft and shaftless mechanisms, incorporates a dancer roller for optimal tension control, and offers a choice between pneumatic brakes or electric motors. It’s also fitted with an automatic web guider for precise material handling.

CUTTING – Features both oscillating blade and circular shear cutting options, equipped with a knife holder that can be adjusted on a shaft or linear guides for diverse cutting needs. It supports various belt pathways for both wrapped or tangent cutting, with blade positioning ranging from manual to fully automatic settings.

BELT – Boasts an overhead passage system with a compact bridge structure, utilizing aluminum idle rollers for smooth operation. It includes a drive roller and a pressure roller, with an optional “S” drive for enhanced material transport.

WINDING – Offers a double shaft winding mechanism with contact rollers for efficient material processing. It provides choices between ball clutched shafts or pneumatic expanding shafts, along with independent contact rollers controlled pneumatically. Tension control is managed through multiple systems, with core positioning either manually, using laser pointers, or through an automatic loader. Reel unloading options include a flag device or a motorized trolley for ease of operation.

AUTOMATION – The machine is governed by a PLC for comprehensive control over all functions, featuring a touch screen operator panel for user-friendly interaction, and a modem for remote monitoring, ensuring operational efficiency and ease of use.

Read more about product and technical specifications under “Datasheet”