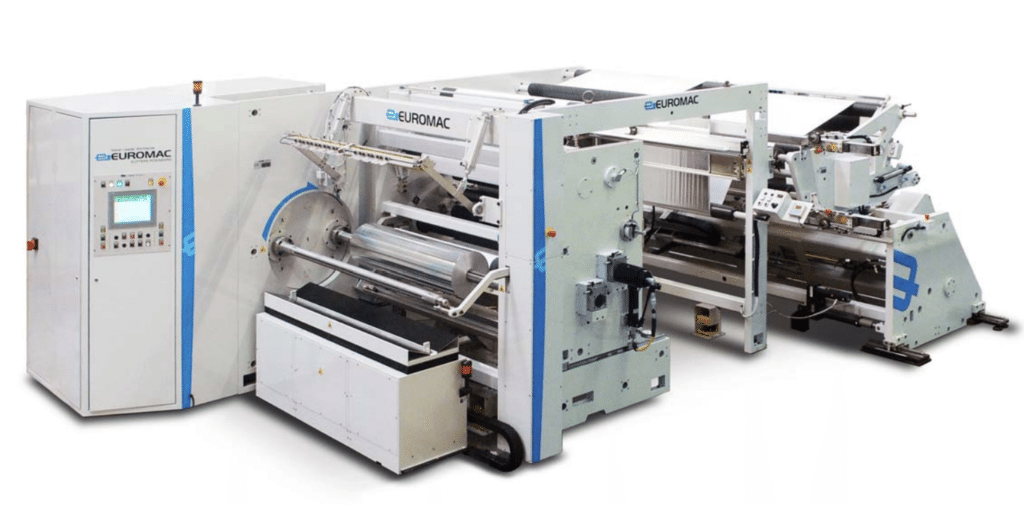

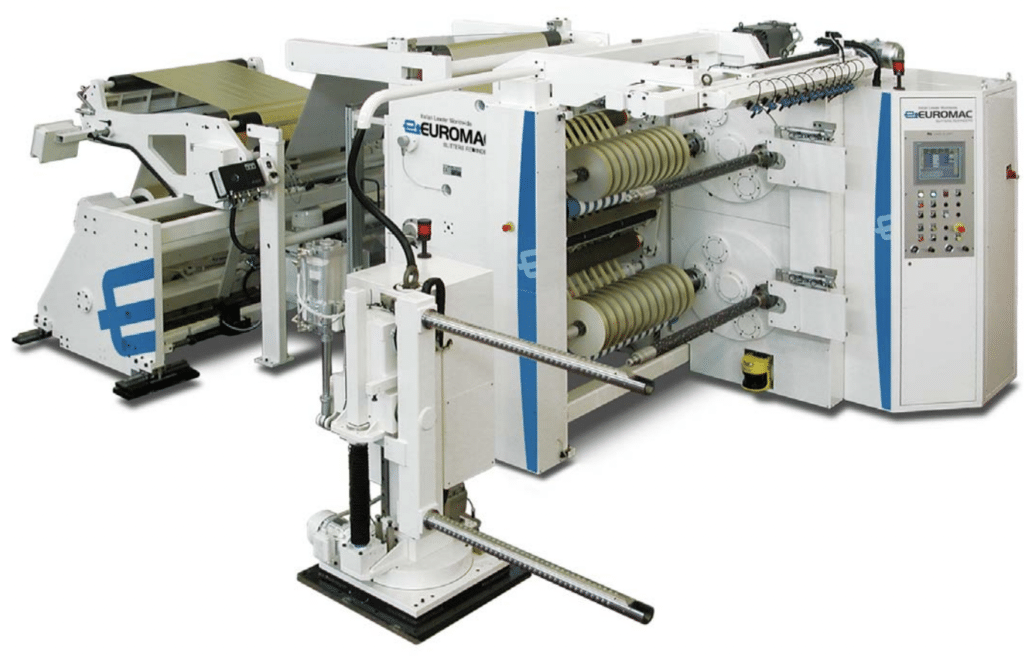

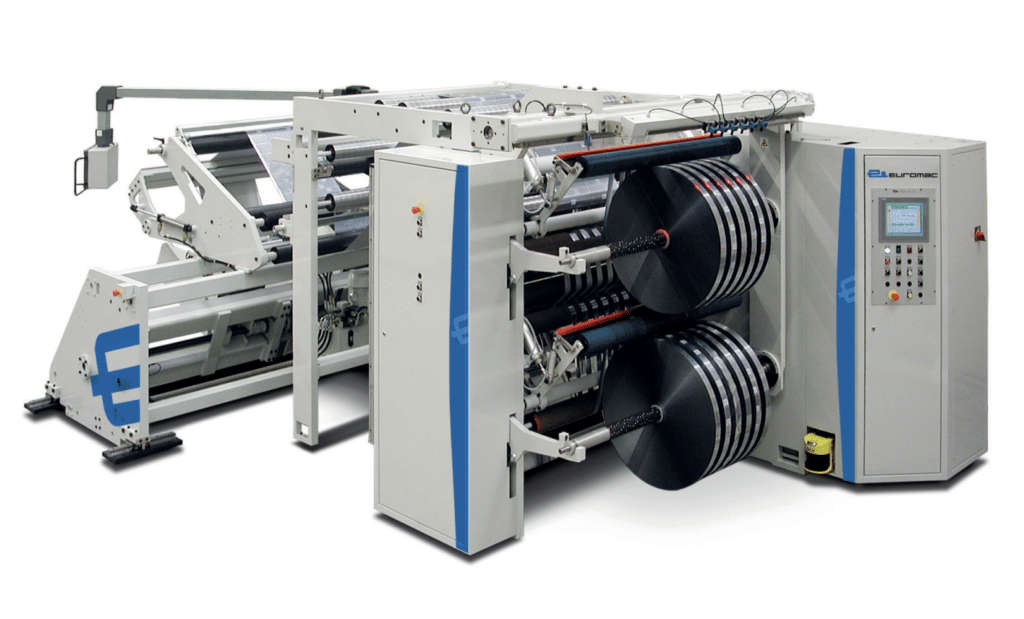

Roll Slitting Machine: Enhanced Features for Precision and Control

Get versatile roll slitting machines for flexible packaging. TB-3 series delivers precise rewinding and cutting: duplex/single shaft functions & automation.

UNWINDER – Offers a distinct unwinder, available with or without a shaft, featuring a dancer roller for precise tension management. Equipped with either a pneumatic brake or an electric motor, it includes an automatic web guider for accurate material alignment.

CUTTING –Provides a cutting system with either a circular shear or an oscillating blade, with blades adaptable to a shaft or linear guides. It accommodates specific tape pathways for either wrapped or tangent cuts, with blade positioning options ranging from manual to fully automatic.

BELT – Features an aerial bridge passage, utilizing idler rollers made of aluminum or given a special treatment for durability. It is equipped with a drive roller and a pressure roller, or an option for a double “S” drive for enhanced material handling.

WINDING – Utilizes a single shaft for winding, supported by contact rollers for efficient material management. Includes a turret for automatic change. Halting the machine for about 30 seconds, and enables transversal cutting in an automatic sequence. Offers shafts that are either pneumatically expanded or ball clutched, with independent contact rollers under pneumatic control. Tension is regulated by multiple systems, and reel unloading can be performed manually or with a motorized trolley for convenience.

AUTOMATION – The Roll Slitting machine is automated through a PLC, ensuring comprehensive control over all functions and operations. It features a touch screen operator panel for easy interaction, and a modem for the capability of remote monitoring, enhancing operational efficiency and ease of use.

Read more about product and technical specifications under “Datasheet”