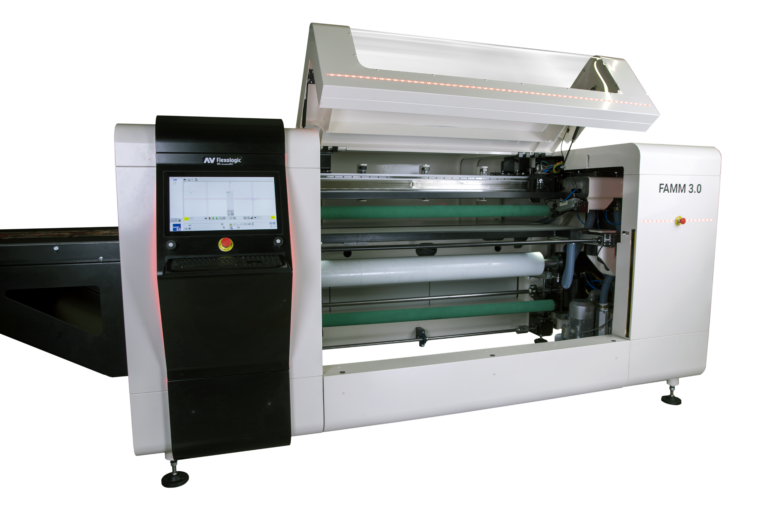

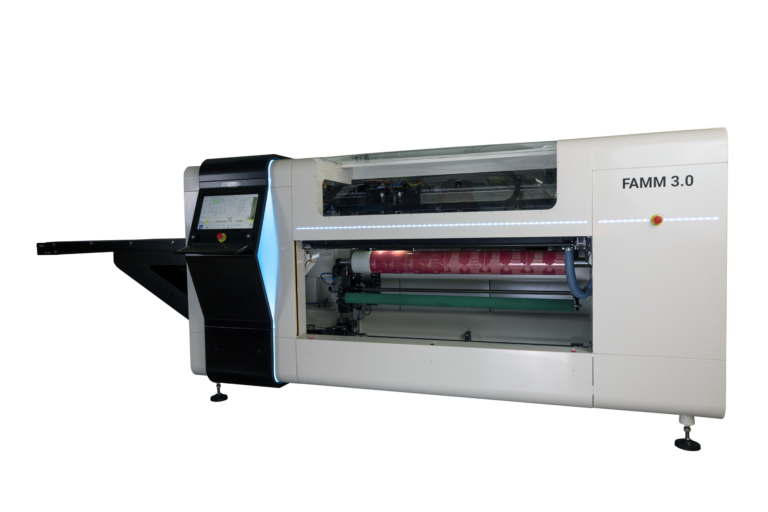

FAMM 3.0 with Peak Precision & Speed for Short Job Runs

The Fully Automatic flexo plate Mounting Machine FAMM 3.0, a third-generation innovation, stands as the optimal choice for short and frequent job runs. It represents the pinnacle of automatic mounting technology, delivering unmatched speed, consistency, and precision. The FAMM 3.0 boasts a rapid 30-second mounting time for each plate with a remarkable 2-micron accuracy, and the flexo printing sleeve change process is impressively quick, taking merely 10 seconds.

FAMM 3.0 Benefits:

- Autonomous mounting operations

- Exceptional mounting precision

- Increased capacity with reduced costs

- Optimal handling with flexo printing sleeves

- Robotic plate loading option

- Robotic mounting and taping capabilities

Product Features:

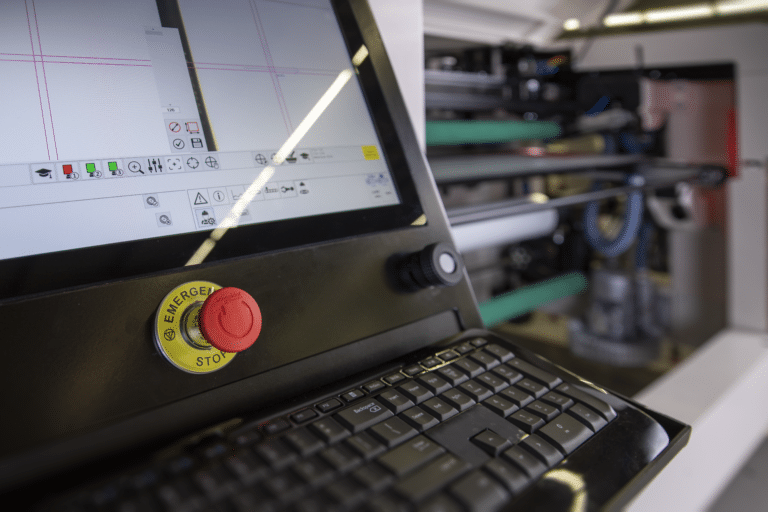

- Fully Automatic Mounting: Flexo plates are placed automatically with incredible precision of 2 microns using a robotic manipulator and an image recognition system.

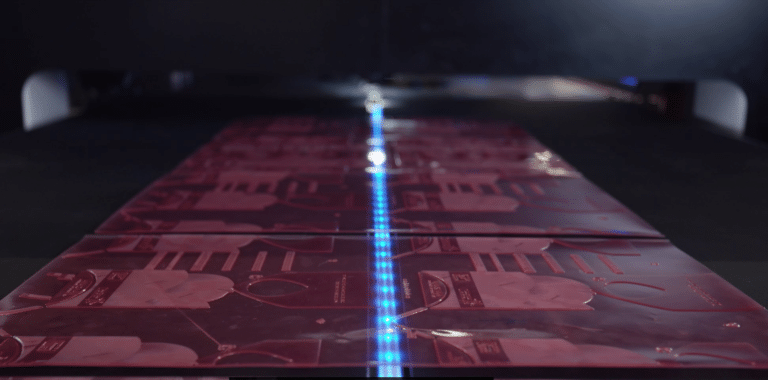

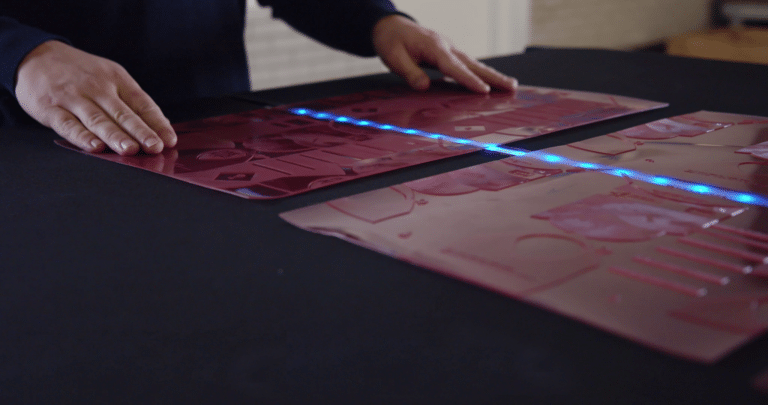

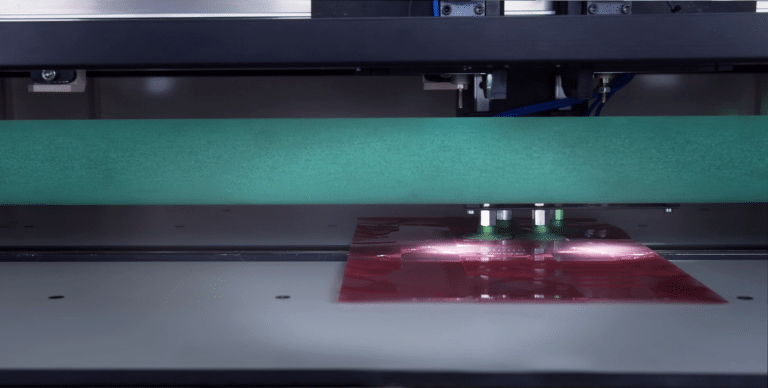

- Conveyor Belt: A new split conveyor belt with QR code reading simplifies the identification of plates, while backlighting and laser lines facilitate the adjustment of plates.

- Robotic Manipulator: The manipulator picks up plates and transfers them precisely to the mounting position, reducing the operator’s workload.

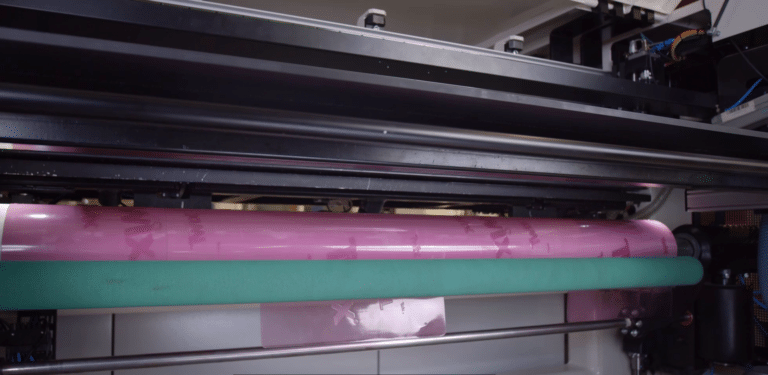

- Two Automatic Pressure Rollers (Patent Pending): A unique pressure roller method where the top roller mounts half of the plates, before the mandrel is lowered to allow the other roller to mount the rest. Meanwhile, the next plate is already positioned for mounting.

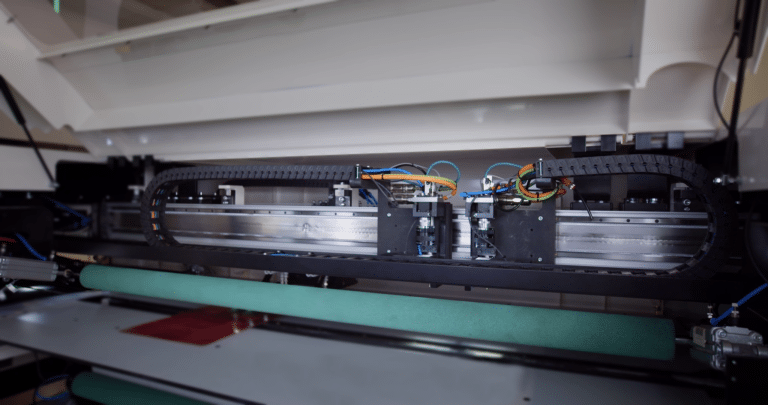

- Automatic Linear Motors (Patent Pending): State-of-the-art linear motors enable quick and precise plate transfer and positioning. Quality control is now three times faster.

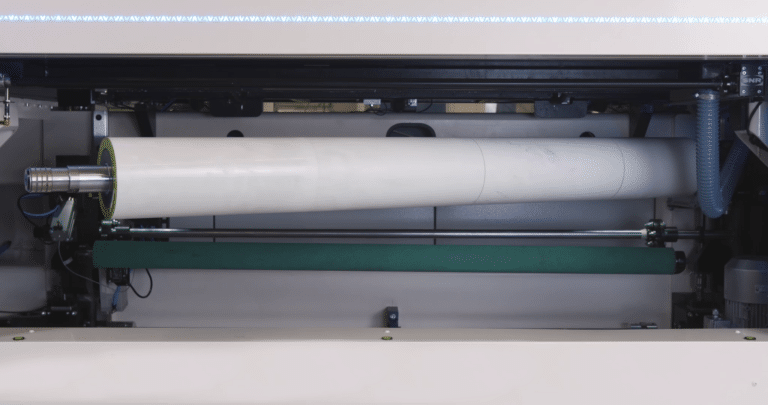

- Automatic Mandrel Rotation: The mandrel performs synchronous movements and rotates automatically, enabling operator-free mounting. After mounting, the mandrel is automatically unlocked.

Read more about product and technical specifications under “Datasheet”