Strong and Lightweight Flexo Printing Sleeve

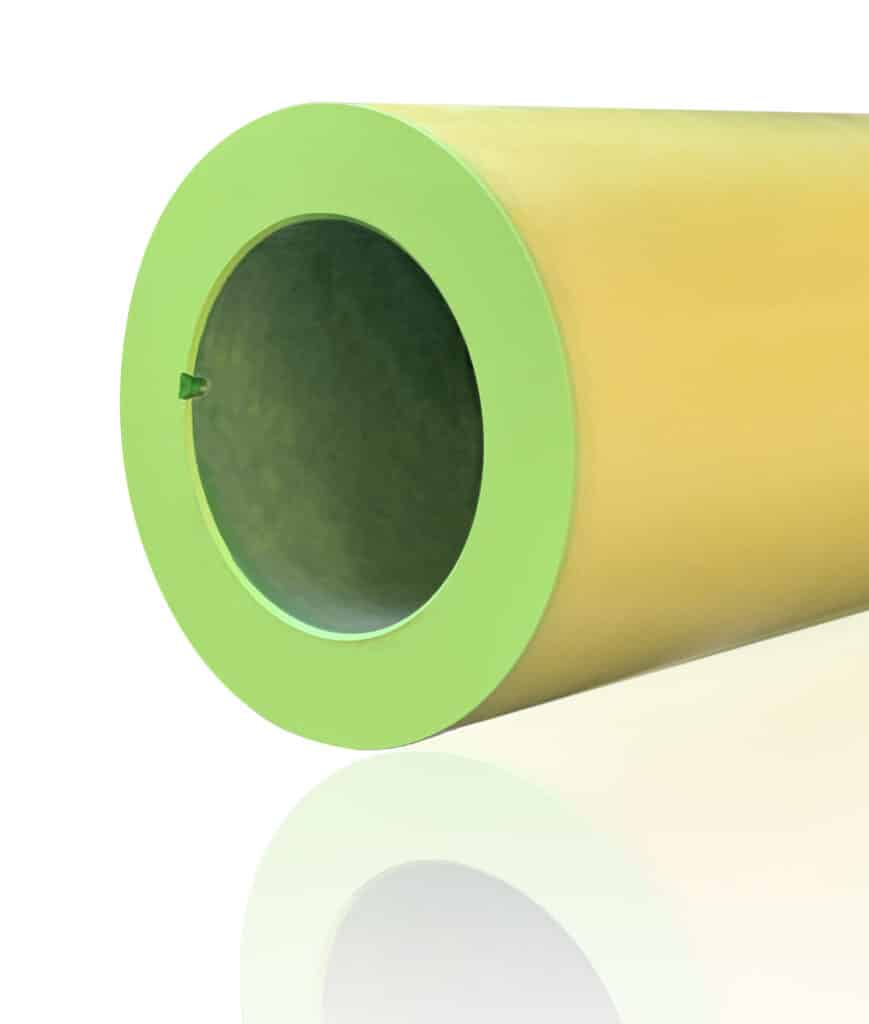

Tech Sleeve Light employs cutting-edge technology and an optimized structural formula to decrease the weight of flexo printing sleeves while enhancing their overall rigidity and durability.

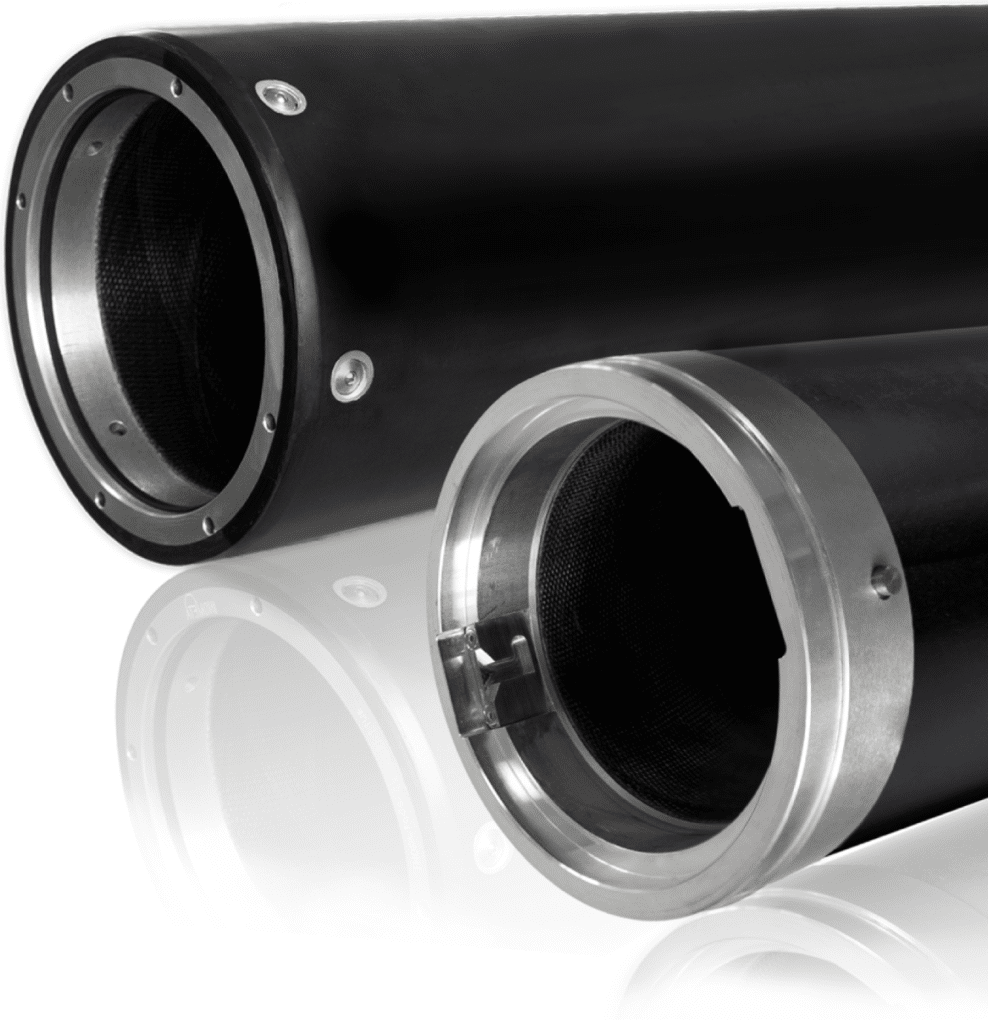

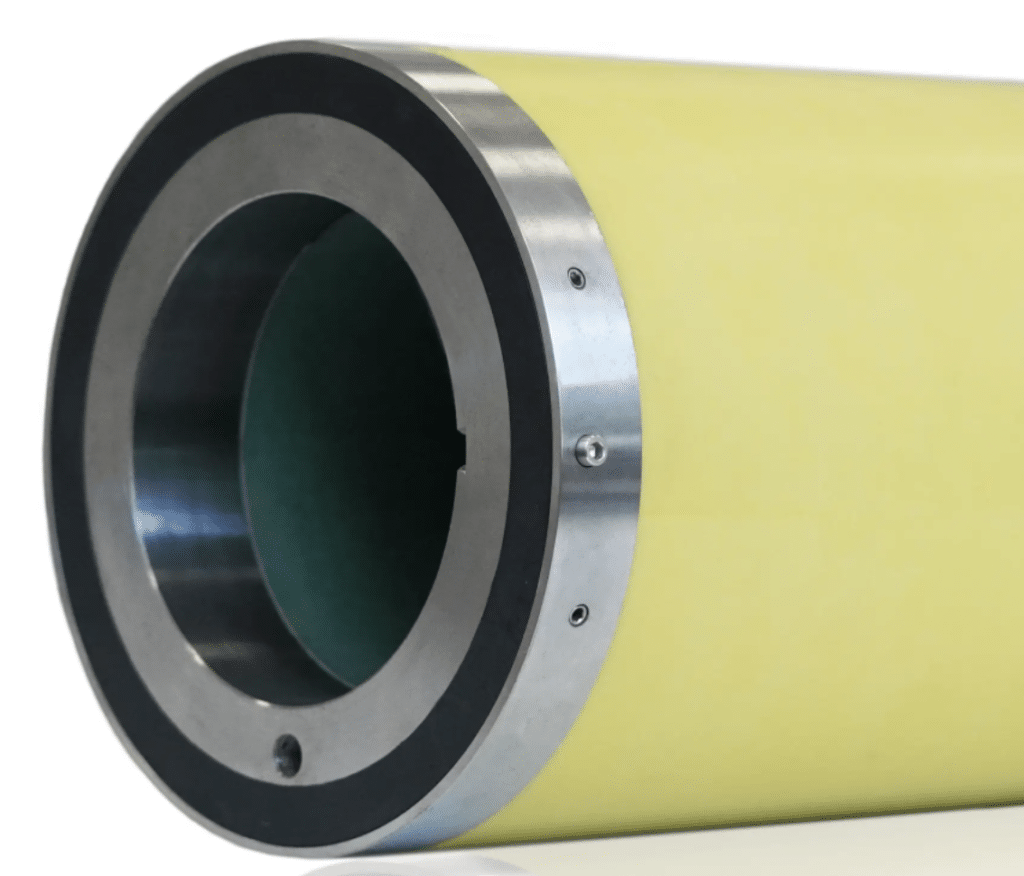

Tech Sleeves features rubber-sealed edges to prevent edge damage and extend the lifespan of the product. Additionally, there’s an option for integrated metal reinforcement in the slots to boost the sleeve’s toughness and ensure its longevity.

Flexo printing sleeves are also referred to as “mounting sleeves” or “flexo plate sleeves.”

Advantages of Tech Sleeve Light:

Up to 40% Lighter Flexo Printing Sleeves: The sophisticated lightweight technology significantly reduces the weight of flexo printing sleeves by up to 40%, making them easier to manage, minimizing impact shock, and ensuring superior print quality.

Reduced Effort and Damage: The lightweight design facilitates easier handling and mounting of Tech Sleeve Light, resulting in less strain for operators and reduced risk of damage during installation and use.

Enhanced Workflow: By lightening the load and improving the manageability of sleeves, Tech Sleeve Light streamlines workflow. This leads to improved efficiency and productivity in production.

Durable Inner Core: Our Tech Sleeve Light features a highly durable inner core made of Dyneema and vinyl ester resin. This ensures the flexo print sleeve’s core withstands the constant pressure from cylinder loading and unloading. Its long-term durability ensures that Tech Sleeve Light remains in excellent condition over time, yielding reliable performance and consistent print outcomes while maintaining dimensional stability crucial for the accuracy and quality of the printing process.

Vinyl Ester Resin Outer Layer: The UV-cured outer layer with a Shore D hardness of 82 makes our sleeves among the most rigid in the flexographic print market. This robust and stiff outer layer ensures our flexo printing sleeves withstand even the most demanding printing processes. Their high-pressure resistance makes them ideal for tasks where precision and quality are paramount.

Variants:

We offer various flexo sleeves to meet diverse needs and requirements in the printing industry:

Rubber-Sealed Edges: Sleeves equipped with rubber-sealed edges effectively prevent edge damage to a mounting sleeve and damage to positioning spindles in printing and mounting machines. Moreover, ink does not penetrate the inside of the sleeve, contributing to a clean and precise printing process.

Smart Sleeve (RFID): Our Smart Sleeve features embedded RFID technology for reading and updating data for identification purposes. This system is fully compatible with both our existing and new Tech Sleeves systems, providing a versatile and seamless solution for object identification and tracking.

Conductivity: Tech Sleeve offers flexo printing sleeves and bridges/adapters certified in accordance with ATEX and NEC HAZLOC standards. This ensures our sleeves meet stringent safety and usage requirements in potentially explosive environments.

Read more about product and technical specifications under “Datasheet”, “Manual” and “Blueprint”.