Efficient charging generator for precise IML charging

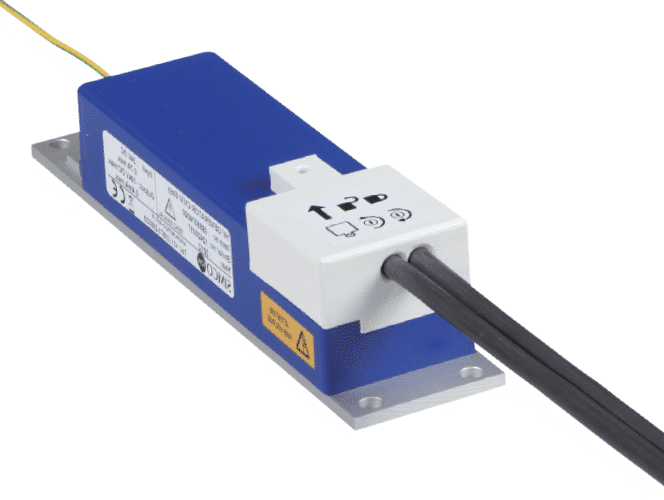

CMM (IQ) Easy is a compact profile charging generator specially designed for IML charging/applications. This unit is equipped with fully integrated high-voltage components and only requires a 24V DC power supply.

With a weight of just 340 grams, this charging generator is easy to install on IML pick-and-place handling systems. It is robust and can withstand the significant G-forces that occur during the IML process.

CMM introduces a unique patented “OK” cycle function. A signal is activated when the labels accumulate an electrostatic charge, indicating the completion of charging. This signal can be used by the machine’s interface to terminate the charging.

Optimization of Injection Molding: Safety and Efficiency Improvements

Another step in the cycle, with the OK signal, indicates that the charge on the mandrel has dropped to a safe level for removing the mandrel from the mold. This innovative feature eliminates the need for guesswork and experimentation in setting up for each IML charging/application or product change.

By utilizing the parameters generated by CMM, the charging time and the overall cycle time for the injection molding process can be significantly reduced. This accelerates the initial setup, changeover, and cycle time, while increasing reliability.

Furthermore, the cycle OK signal provides detailed information about the process. If the charge level deviates more than 10% from the set point during the charging process, the cycle OK signal will not be activated. This signals that the charging was unsuccessful, which may be due to the absence of one or more labels and results in voltage leakage.

The indication LEDs on both sides of the end of the CMM unit also provide general information about the unit’s status.

Benefits:

- Compact Size

- Featherlight Design

- Resilient to Intense G-forces

- Integrated Cycle OK Indicator

Product Features

- Versatile Output Voltage Range: 0 – 20 kV

- Optimized for IML Tasks: Tailored design for In-Mould Labelling applications

- Strategic Robot Arm Placement: Ideal for positioning on the robot arm during IML procedures

- Durable and Efficient Design: Compact yet resilient against G-forces

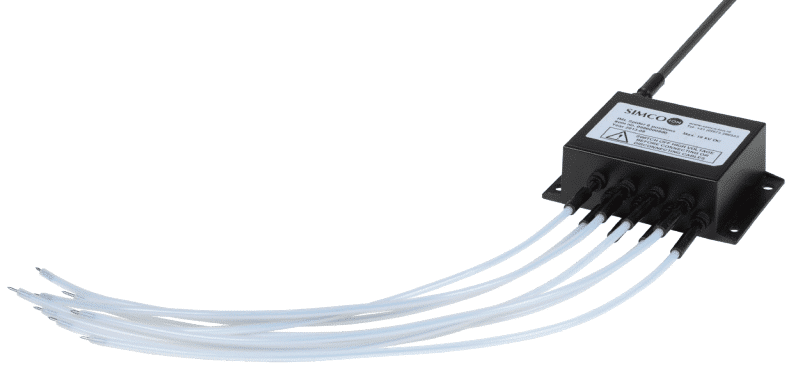

- Eliminates Need for High Voltage Cables: No high voltage cable required through the cable channel

- Significantly Reduces Charging Time: Cuts down the total cycle time of the injection moulding process

- Integrated 24V DC High Voltage Supply

- Removable high-voltage distribution block

- Enhanced Visibility with LEDs: Equipped with LED indicators on both sides for status monitoring

Read more about product and technical specifications under “Datasheet”, “Manual”, and “Blueprint”.