Industrial Spot and Process Cooling with Vortex Tubes

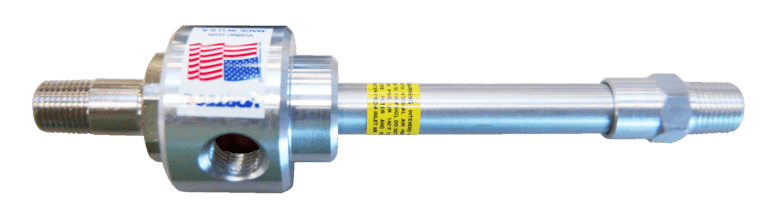

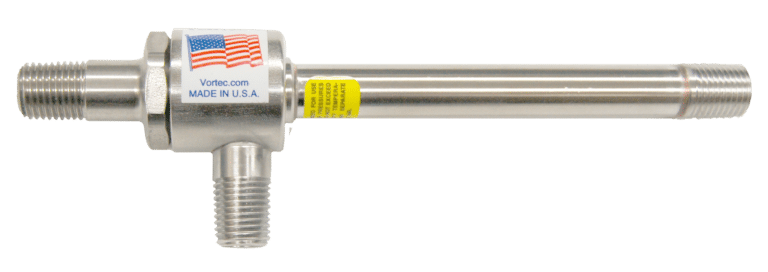

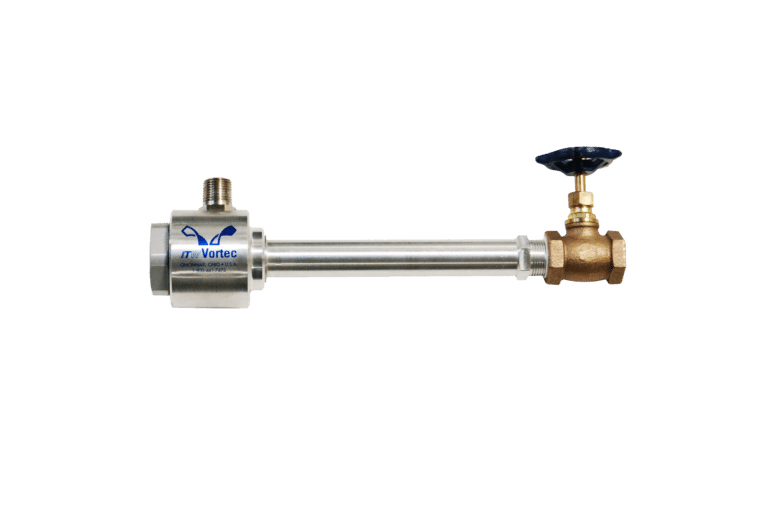

Vortex Tubes, capable of generating up to 6000 BTU/hr (1757 watts) of refrigeration and achieving temperatures as low as -40 deg, are ideal for a variety of industrial spot and process cooling requirements. These tubes are noted for their high reliability and cost-effectiveness, as they have no moving parts and do not require an electrical connection at the site of cooling. Vortex Tubes provide immediate cooling by using compressed air that spins within the tube to divide the air into separate cold and hot streams.

Primarily used for cooling, these tubes can also serve heating purposes by redirecting the exhaust hot air.

Invented by French physicist Georges Ranque in 1930 and industrialized by Vortec in the 1960s, Vortex Tube technology has since been widely utilized across various industries for machine cooling, assembly line cooling, process cooling, and in testing and measurement applications. Discover how it works.

Benefits

- Provides Immediate Cooling On Demand

- Offers the Most Cost-Effective Refrigeration Per Unit Among All Cooling Methods

- Fully Customizable and Portable Cooling, Effortlessly Relocatable as Required

- Designed to Fit and Cool in Extremely Tight Spaces

- Minimal Maintenance Needed Compared to Other Refrigeration Techniques

- Eco-Friendly Operation Without the Need for Refrigerants or Chemicals

- Simple Installation Process: Just Connect to Compressed Air and Operate

Product Features

- Completely Maintenance-Free with Zero Moving Parts

- Ensures Cycle Repeatability to Within +/- 1 Degree

- Capable of Lowering Compressed Air Inlet Temperature by Up to 100 deg F (55 deg C)

- Operates Independently of Electricity at the Cooling Location

- Provides Cooling to Temperatures as Low as -40 Degrees Without Refrigerants

- Compact, Lightweight Design for Easy Transportation

- Flexibly Adjustable to Suit Various Cooling Requirements

- Dual Functionality with Heating Capability up to 200 deg F (93 deg C) Using the Same Tube

- Available in Aluminum (208 and 308) and Stainless Steel (208SS) Models

- Offer Replacement Generators for Cooling Modification or in Cases of Contamination

Read more about product and technical specifications under “Datasheet”, “Manual”.