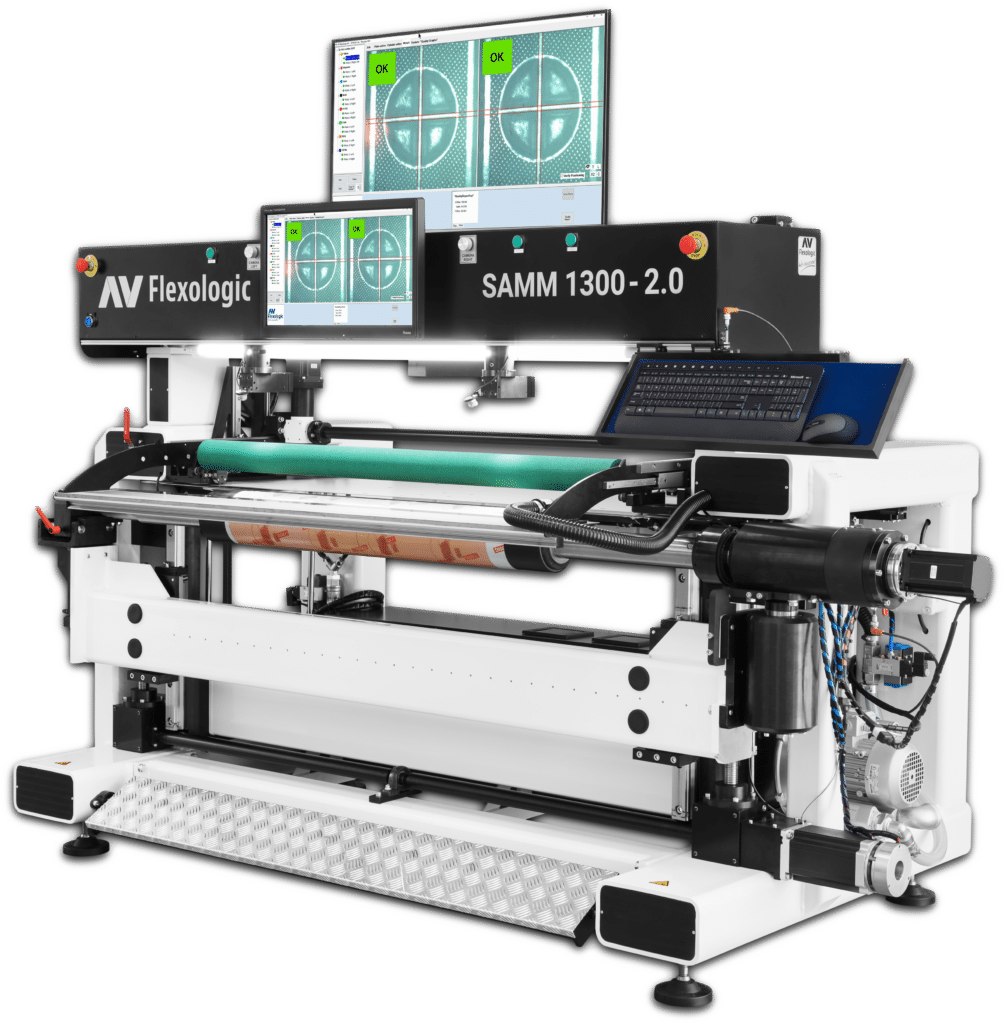

Newest Automatic Plate Mounting Machine SAMM 3.0

Our newest and modern SAMM 3.0 is one of the fastest and most accurate automatic flexo plate mounting machines with unmatched repeatability and speed. SAMM 3.0 comes with a completely new mechanical, visual, and user interaction design. With the latest SAMM 3.0 you can achieve high-quality plate mounting with minimal operator interaction, ensuring an accuracy of 5 microns and a rapid mounting speed of under 30 seconds per plate.

The Benefits of Using SAMM 3.0

- Automatic & extremely easy plate mounting

- Eliminate mounting mistakes, reducing press downtime

- High safety standards

- Almost not dependent on any operators

- Highest accuracy, repeatability & speed (under 30 seconds per plate)

- Software features for enhanced print jobs efficiency

The Unique Features of SAMM 3.0

- High saftey standards: This machine is equipped with high safety standards and a variety of features that make its use even easier

- Backlight system: The third generation of SAMM incorporates backlight technology to enhance image recognition of mounting marks, providing optimal illumination for its ultra-high-definition monochrome cameras. This backlight system improves plate positioning accuracy, boosting the precision and efficiency of SAMM 3.0.

- Patented image recognition system: The Image Recognition System verifies the alignment of mounting marks to ensure the printing plate is accurately positioned on the sleeve.

- Robotic plate positioning: The machine uses a robotic table and patented Image Recognition to automatically position the flexo plate with an extreme accuracy of 5 microns.

- Automatic ultra HD cameras: The latest HD monochrome cameras with an extended camera beam automatically move into the precise mounting position.

- Automatic pressure roller: Ensures even mounting without any air inclusions, requiring no operator interaction.

- Vacuum table: To ensure maximum accuracy, the vacuum system secures the plate to the robotic table before positioning.

- Quality report: The mounting marks are checked, and a PDF is automatically generated with the Image Recognition measurements.

- Vertically moving cylinder: It maintains a consistent distance between the cameras and the plate, eliminating the need for lens focusing. Additionally, the cylinder rotates automatically.

- Easymount software: The Easymount software facilitates quick job creation and storage in under 1 minute. Leveraging the machine’s cameras, the software identifies the targets and calculates the distance between them.

Read more about product and technical specifications under Datasheet