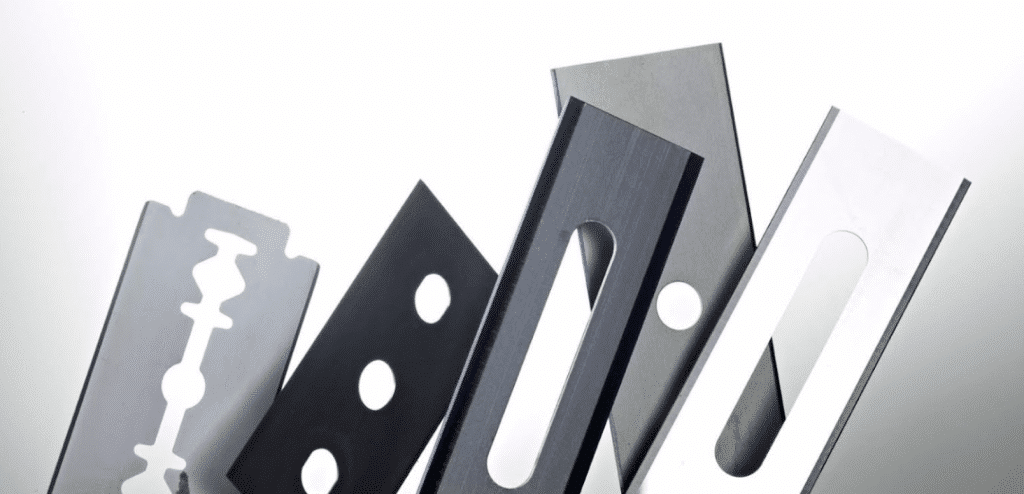

Industrial Razor Blades of High Quality for Precise Cuts

Industrial razor blades play a critical role in machines that cut soft and semi-rigid materials. These blades must meet high standards of precision, reliability, and performance to ensure that the final product is of the highest quality. In many industries, the quality of the cuts made by the machines directly impacts the final product. A precise and clean cut enhances the product’s aesthetic appeal and makes it easier to handle and package. On the other hand, an uneven or rough cut can significantly reduce the product’s quality and make it more challenging to handle.

Applications of Industrial Razor Blades

Industrial razor blades are used in a wide range of machines across many industries, including:

In the flexible packaging industry, razor blades are used in machines that cut films, foils, and other materials used for packaging products. These blades must produce precise and clean cuts to ensure that the final product is of the highest quality.

In the printing industry, razor blades are used in machines that cut paper and other materials used in printed products. These blades must produce clean and precise cuts to ensure that the final product has a professional appearance.

In the converting industry, razor blades are used in machines that convert materials from one form to another. Such as converting rolls of film into bags or sheets. These blades must handle a variety of materials and produce precise cuts to ensure that the final product meets the required specifications.

In the paper industry, razor blades are used in machines that cut paper into precise sizes for further processing. These blades must be able to handle delicate paper materials. Produce clean cuts to avoid damage to the final product.

These are just a few examples of the many industries that use industrial razor blades. The specific application and the type of material being cut. Will determine the requirements for the blade. Such as the material, coating, and sharpness, to ensure that the blade meets the specific needs of the application.

Which Industrial Razor Blades to Choose?

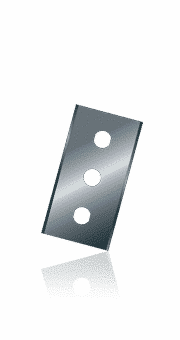

It is essential to choose blades that are specifically designed for the type of material being cut and the intended application. The material and coating of the blade should be tailored to the cutting process to ensure optimal results. In some cases, surface coatings are applied to reduce friction and increase wear resistance. Additionally, the sharpness of the blade is crucial for its performance. A dull blade can produce poor quality. Conversely, a blade that is too sharp can result in excessive wear on the blade.

To meet these requirements, industrial razor blades are made from high-quality materials such as stainless steel. The cutting edges are further protected with hard coatings that increase wear resistance and reduce friction with the material being cut.

If you are interested in learning more about our razor and industrial blades, feel free to contact us for further information or a non-binding offer.