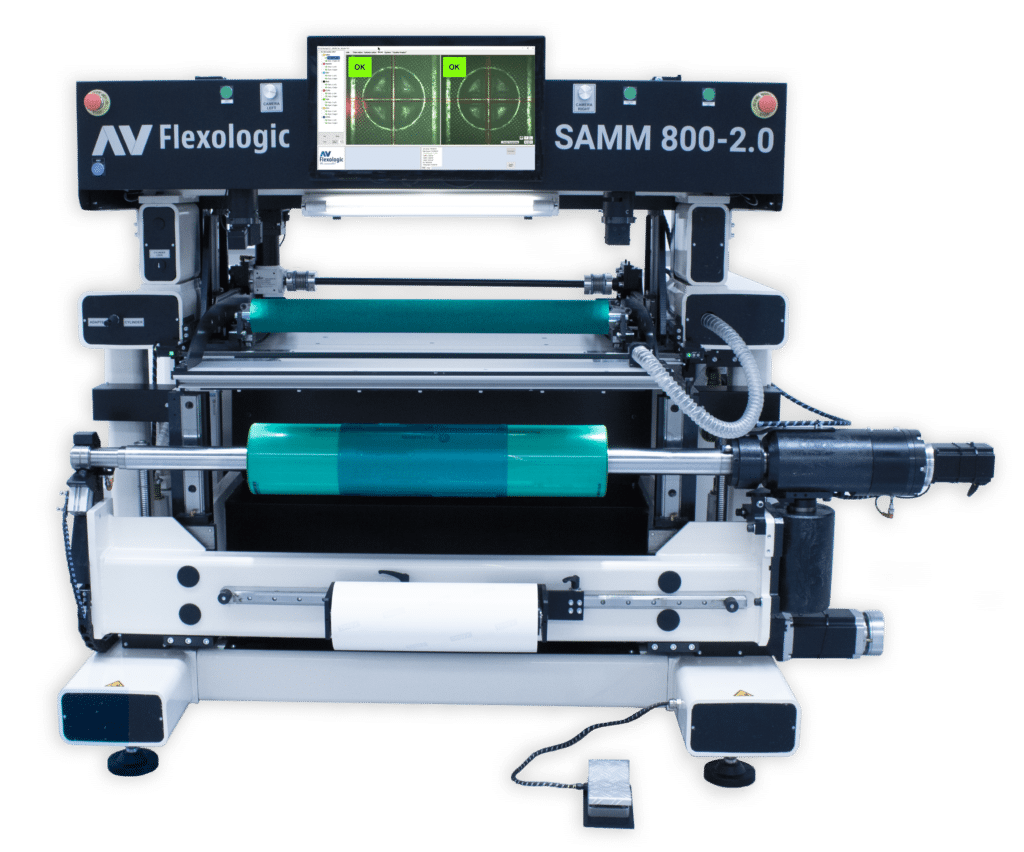

Precision & Ease with Automatic Mounting Machine Upside-Down

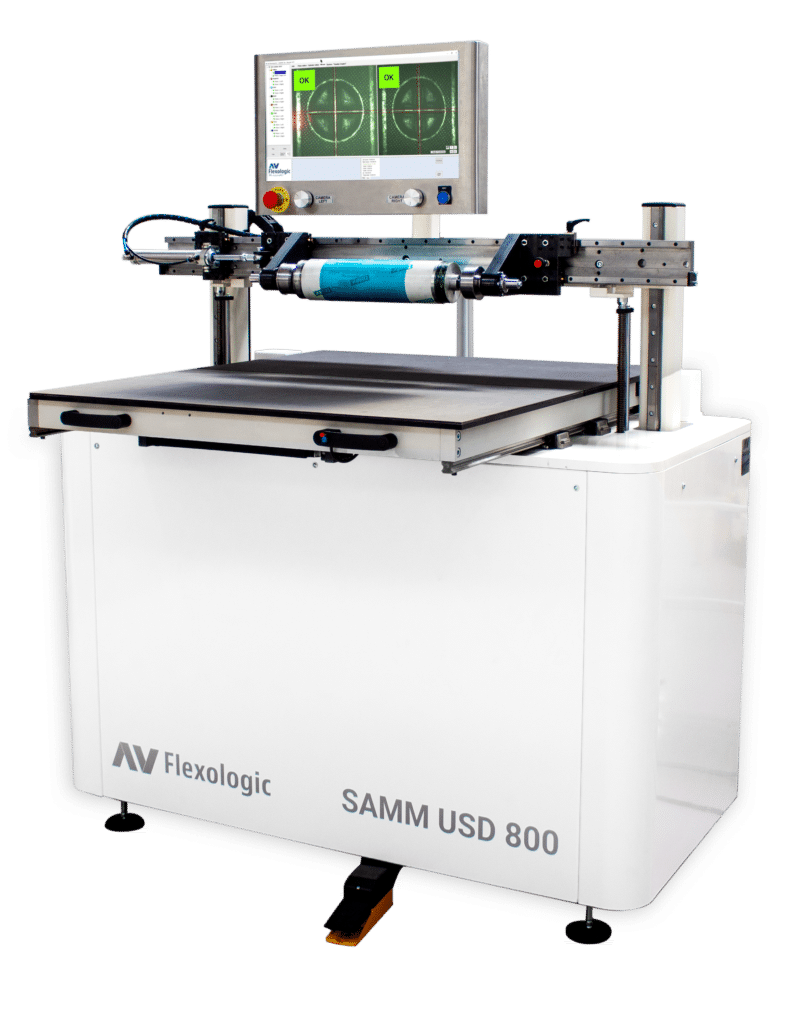

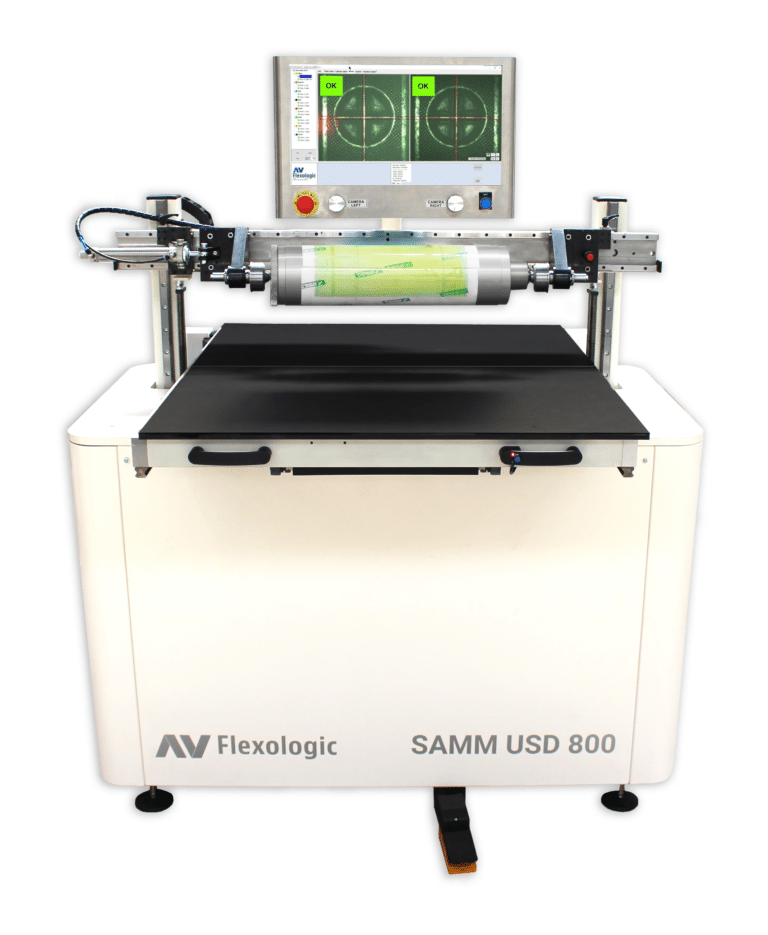

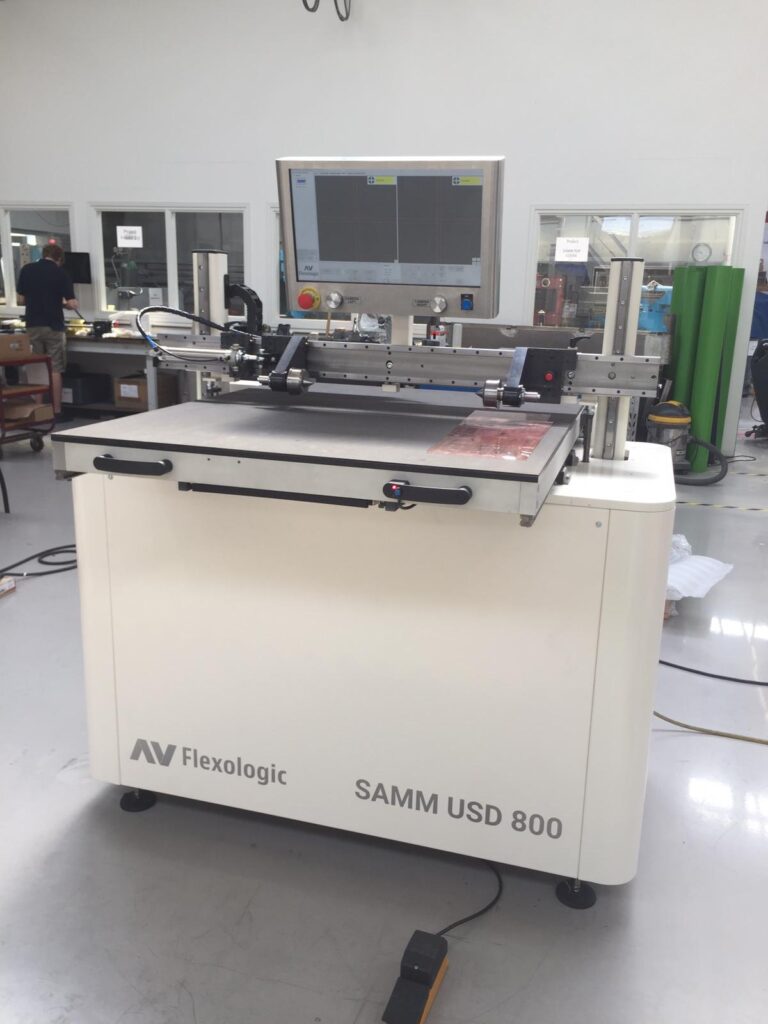

The Automatic Mounting Machine Upside-Down SAMM USD offers exceptional precision, speed, and user-friendliness for flexo plate mounting in label production. This machine simplifies mounting to a point where minimal operator expertise is needed. Utilizing its patented Image Recognition software and a cushioned vacuum table, it automatically positions the plate with remarkable accuracy.

SAMM Upside-Down Benefits:

- Precise Automatic Plate Positioning (5μm)

- Rapid and Simple Mounting Process

- Effective Mounting Free of Air Inclusions

- Convenient Job Creation and Storage System

- Robust and Durable Build

Product Features:

- Advanced Image Recognition: Accurately measures the position of mounting marks with 5-micron precision, ensuring exact plate placement.

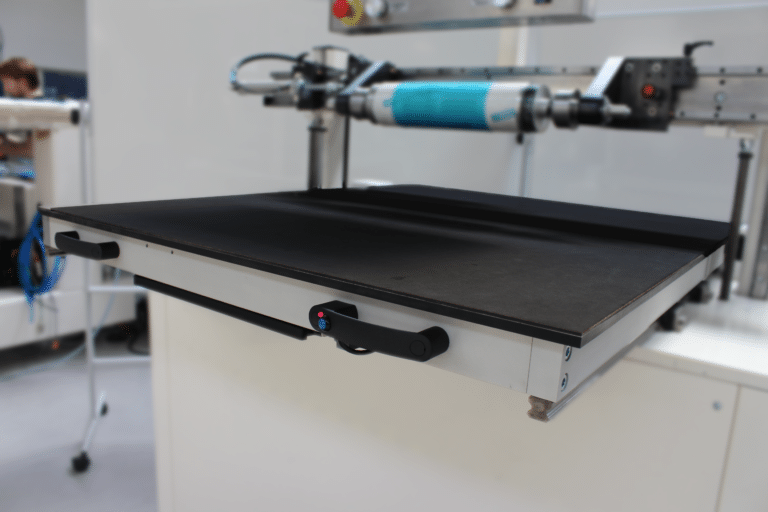

- Vacuum Table with Cushioning: A large, robust vacuum table that not only automates plate positioning but also prevents air inclusions.

- Automated Movement Cameras: Features high-resolution Ethernet cameras that automatically adjust their position, situated below the cushioned table.

- Mounting Accuracy Verification: Post-mounting, the system uses Image Recognition to assess accuracy against predefined tolerances, confirming mounting precision with an ‘OK’ signal.

- Customizable Cone System: A pneumatic clamping system that operates with 2 (or more) cones, tailored to specific requirements, ideal for securing cylinders and flexo printing sleeves.

- Windows 10 Integration: Incorporates an icon-based AV Flexologic mounting software on Windows 10, designed for straightforward job creation and storage, with a user interface optimized for the best operator experience.

Read more about product and technical specifications under “Datasheet”