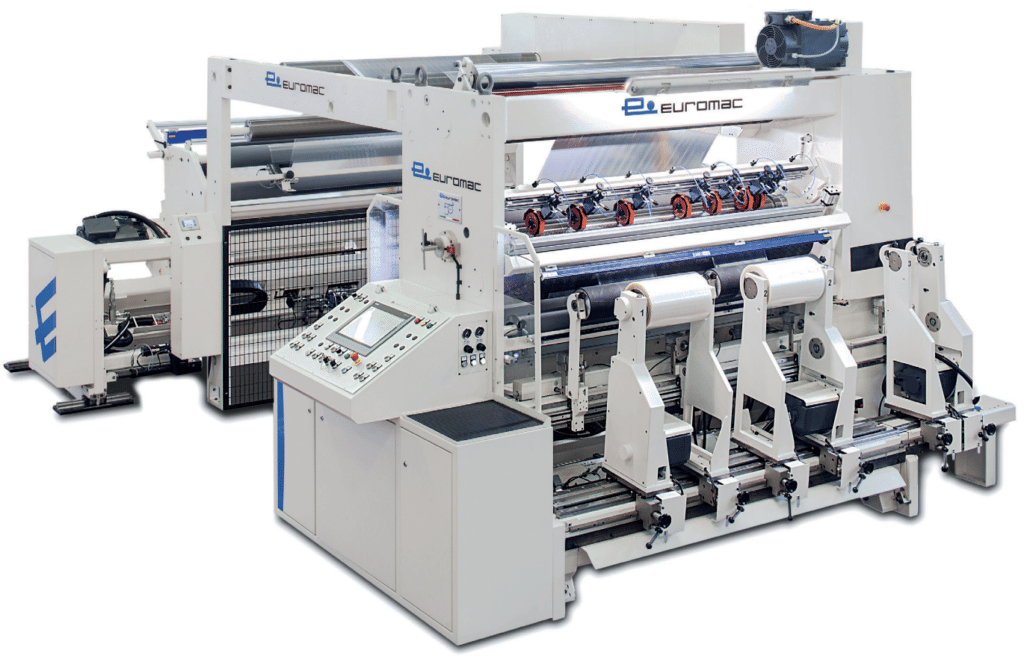

Centre Drive and Lay-on Rolls Slitter Machines – TB-6M

Powerful roll slitter machines TB-6 series for flexible packaging with a high degree of automation and movable carts for efficient film handling.

UNWIND – Choice of Shaftless or Shafted Unwinding. Tension managed by dancing roller. Operated via Pneumatic Brake or Electric Motor. Automated edge-guiding system.

SLITTING – Cutting technology featuring oscillating Razorblades and/or Shear-cut circular blades. Blade holders designed for shaft or linear bearings. Tailored web routing for Wrap-cut or Tangent-cut. Blade positioning adjustable from manual to semi-automatic, up to fully automatic.

WEB PATH – Elevated web routing system. Utilizes aluminum idle rollers. Equipped with a driven main pull roll, complemented by a pressure roller or an “S” wrap configuration.

REWIND – Central and surface rewinding functionality. Rewind stations powered by individual a.c. brushless motors. Linear bearings for swift adjustment of rewind stations. Equipped with multiple tension regulation systems for central and surface drives. Simplified roll unloading via manual or powered carts.

AUTOMATION – Comprehensive PLC integration for operational control Interactive touch screen for user interface. Modem-enabled for remote diagnostics and oversight.

Read more about product and technical specifications under “Datasheet”