Idle Rollers for Enhanced Efficiency Across Various Industries

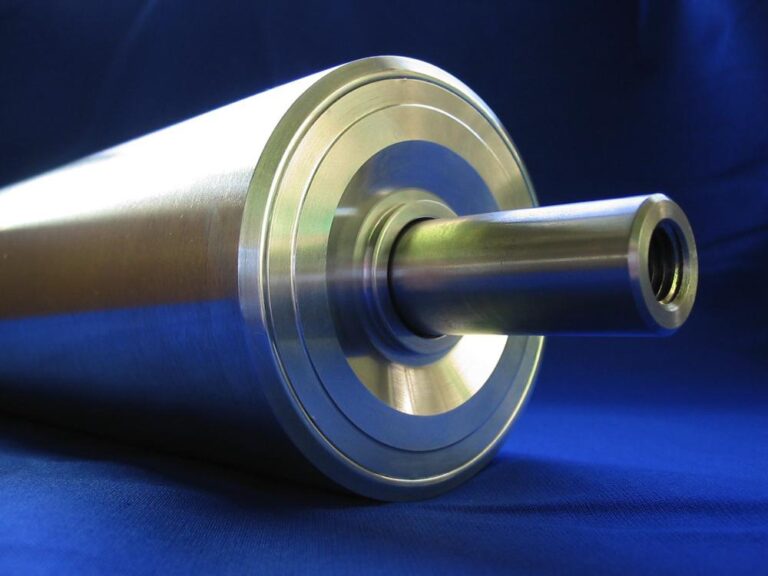

Idle rollers are designed to guide, support, and shape materials as they move through different industrial processes. They are engineered to minimize friction and improve material flow, leading to increased efficiency and faster production speeds.

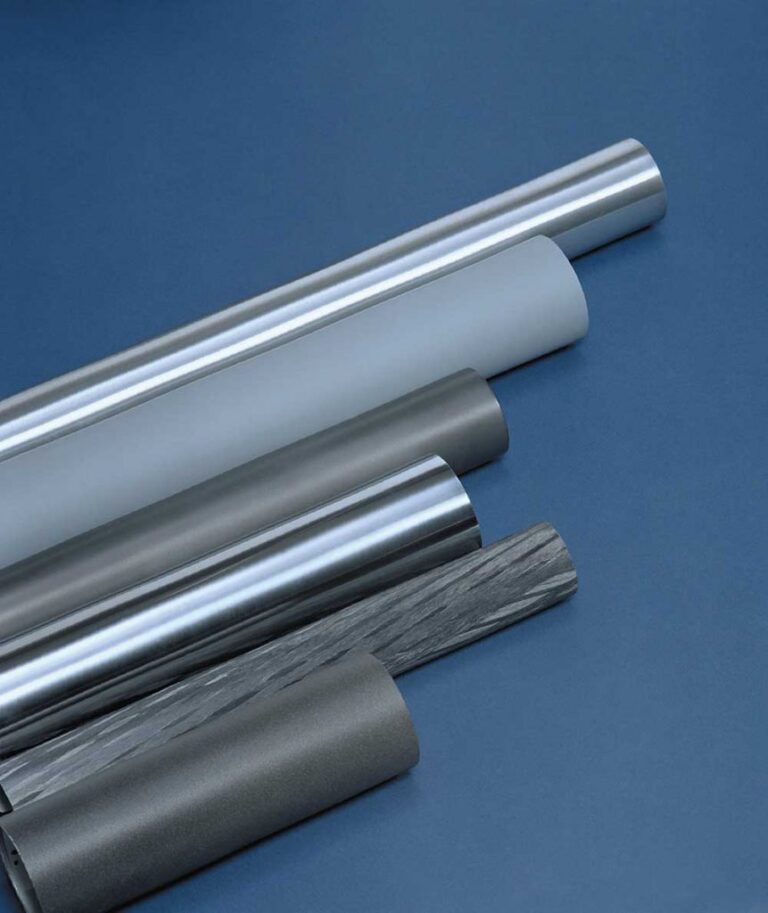

Constructed from various materials like aluminum, rubber, chrome, and steel, these rollers can be customized to meet specific industry needs. Options include smooth, polished surfaces or textured finishes such as sandblasted, striped, diamond-patterned, edged, ground, or grooved.

These rollers find application in a wide range of machinery, including extrusion machines, flexo and gravure printing machines, lamination machines, and more.

The lightweight and versatile nature of aluminum idle rollers makes them ideal for low-tension applications and handling smaller material volumes. Additionally, their durability and resistance to corrosion ensure long-lasting performance.

Benefits of Our idle Rollers

- Enhanced Efficiency: By reducing friction and improving workflow, it can lead to greater efficiency and increased production speeds.

- Long-Term Performance: Built to last, reducing the frequency of replacements and thereby saving time and costs in the long run.

- Customization: Tailored to meet specific industry needs, providing a bespoke solution that boosts overall performance.

- Versatility: Suitable for a wide array of applications, making them a versatile option for numerous industries.

All our idle rollers are manufactured to customer specifications. We supply both machine manufacturers (OEMs) and production companies. Our aim is to deliver versatile and reliable high-quality solutions. If you’re interested in learning more about our products, please feel free to contact us. Our team is eager to answer any questions and provide further details.